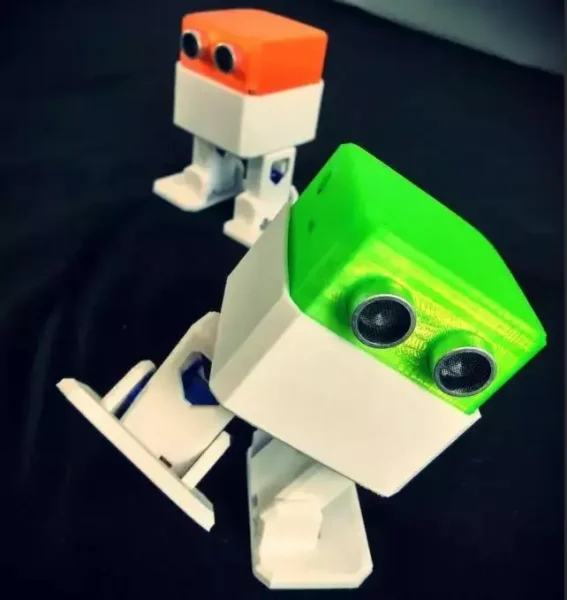

Toys and Animation

3D printed toys anime hand-me-downs

3D printed toys animation hand Using advanced 3D digital modeling technology to design and produce animation 3D model, combined with 3D printing technology, which is a new digital way of animation design and production. Compared with the traditional animation prototype production means, some advantages of digital design, promote the innovation of animation production mode and the improvement of design level.The realistic models provide a unique opportunity for the animation and entertainment industry.

In the animation and entertainment market segment field, how to create the most realistic prototype to reflect the original intention of designers is very important. Due to the limitations of materials and production tools, the production of traditional handmade prototypes is difficult to meet the increasingly stringent industrial needs in terms of talent demand and design and production methods, which is the pain point of traditional handmade production.

(1) High Requirements for technical personnel The design and production of traditional manual prototypes have too high requirements for talents.The work of a prototype master is equivalent to a traditional sculptor who creates characters in anime by using sculptural materials and techniques.The nature of its work determines that the prototype division has the professional technology of a sculptor, and the charm of the animation image is very clear.Traditional hand production mainly use some mud or clay as material, although in the decades of Japanese prototype teachers have invented what they think the most to use clay material, but compared with digital modeling software “virtual clay”, it still has many disadvantages, such as in clay material dry hardening after big modification is almost impossible.Traditional clay materials determine that the need for the prototype engineer is extremely experienced, in the production can not appear obvious mistakes.The high requirements for technical personnel are also reflected in the meticulous production. When using traditional clay materials to make more than 10 cm high characters, the character’s face is often only the size of the thumb nail, and its small size will also bring great challenges to the production.All of these are due to the difficulty of traditional materials.Therefore, for quite a long period of time, it is difficult for Chinese college students to enter the mobile industry.However, the use of digital modeling technology design in computers does not exist such a problem, due to its easy to modify the characteristics, it will relatively reduce the requirements for talents.

(2) It is difficult to make modular design and production. A large number of different costumes and dynamic shapes of the same role. If the modular design and production can be realized, it will greatly improve the efficiency and production quality.Modular design and production refers to the design and production methods that different model parts can be reused, such as body parts, hats, clothes, accessories, etc., which can be used directly in the next design.Obviously, the use of clay hand prototype is not directly made into another set of hand shape, that is to say, the use of traditional hands almost from beginning to end, which is undoubtedly to increase the difficulty of production, especially greatly increased the production cost.

(3) Part of the toxicity of traditional hand modelling, is the use of mud (China), American soil (expensive), powder clay (Japan), atomic ash (Japan), AB soil, etc., including atomic ash and some inferior mud has high toxicity, under the prototype division long-term contact, toxic ingredients through the skin.

A new technology, toy 3D printing, is gaining popularity. This revolutionary technology not only changes the traditional way of making toys, making them easier and faster to make but also satisfies the need for personalization, allowing toys to better fit the actual needs of children.

The process of toy 3D printing is divided into three steps: first, a library of 3D printing models needs to be prepared, then the models and materials are selected, and finally, the 3D printer is activated. Toy 3D printing is more accurate than traditional production methods, enabling the scanning of any image, as well as the ability to meet the design needs of any size and shape.

In addition, toy 3D printing technology supports reuse, and it can effectively save material and labor costs. In addition, toy 3D printing allows for the production of larger, more detailed toys, so that children have more opportunities to explore new toys and enjoy the excitement.

Toy 3D printing truly gives kids the opportunity to enjoy more and better toys – using this technology, kids can explore new ideas, achieve what their hearts desire, build the perfect toy, and experience the magic of the world with their own hands.

PMAX3D is a high-tech enterprise, focusing on the development and manufacture of 3D equipment, providing 3D equipment to meet the needs of different industries. We are committed to providing the best quality products and services to our customers with the tenet of “technological innovation, reasonable price, and customer first”. We have an advanced manufacturing processes and the most advanced production equipment, independently developed a series of 3D scanning and 3D printing equipment, products can be widely used in a variety of industries, we are committed to providing customers with satisfactory solutions to enhance customer productivity and competitiveness.